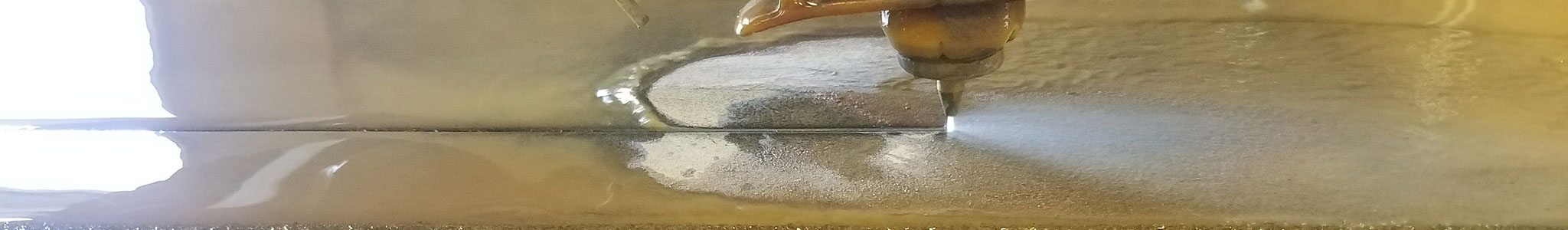

The power of water. It can create canyons, fight fires, and gives life to our planet. Soft as rain drops, or powerful enough to cut the thickest materials. By embracing the principals of 5-axis technology, the Flow waterjet can provide higher accuracy than ever before.

Industrial waterjet cutting has been around since the 1930’s. With the invention of abbrasive waterjet cutting in the early 80’s it quickly became a popular choice in many areas of industries.

A pioneer with 20 years of waterjet cutting experience, Huron Fabrication is a preferred choice for waterjet cutting, ultra-thick exotic alloys, and complex contours.

Operations:

- Abrasive Waterjet

- 2 Flow XD 5-Axis Waterjet Cutting

- Dynamic Waterjet Cutting